Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV Detail:

Donpipe 302 HCFC-141b base blend polyols for pipeline insulation

INTRODUCTION

This product is a type of blend polyols premixed with HCFC-141B, which is specially researched for rigid PUF to produce thermal insulation pipes. It is widely used in steam pipes, liquefied nature gas running pipes, oil pipes and other fields. The characteristics are as follows:

(1) good flowability, by regulating formula to suit different pipe diameters.

(2) excellent low temperature dimensional stability

PHYSICAL PROPERTY

| Appearance |

Light yellow to brown transparent liquid |

| Hydroxyl value mgKOH/g |

300-450 |

| Dynamic viscosity(25℃) mPa.S |

200-500 |

| Density (20℃) g/ml |

1.10-1.16 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

TECHNOLOGY AND REACTIVITY (Component temperature is 20℃, the actual value is varied according to pipe diameter and processing condition.)

|

|

Manual mixing |

High pressure machine |

| Ratio(POL/ISO) |

1:1.10-1.1.60 |

1:1.10-1.60 |

| Rise time s |

20-40 |

15-35 |

| Gel time s |

80-200 |

80-160 |

| Tack free time s |

≥150 |

≥150 |

| Free density kg/m3 |

25-40 |

24-38 |

FOAM PERFORMANCES

| Mold density | GB 6343 | 55-70kg/m3 |

| Closed-cell rate | GB 10799 |

≥90% |

| Thermal conductivity (15℃) | GB 3399 |

≤24mW/(m.K) |

| Compression strength | GB/T8813 | ≥200kPa |

| Water absorption | GB 8810 |

≤3(V/V)% |

| Dimensional stability 24h -30℃ |

GB/T8811 |

≤1.0% |

|

24h 100℃ |

≤1.5% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

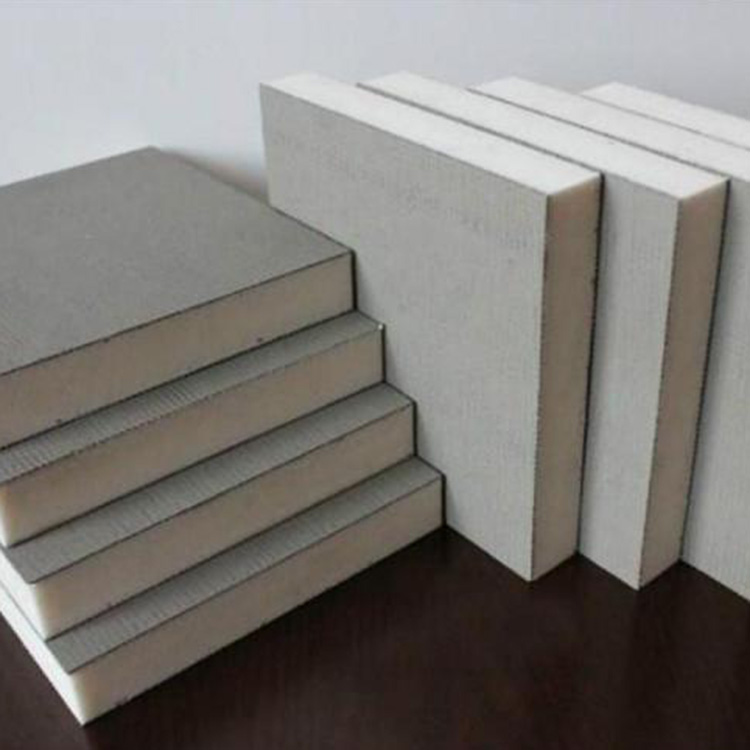

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV , The product will supply to all over the world, such as: US, Hungary, Qatar, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!