Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV Detail:

Donpipe 302 HCFC-141b base blend polyols for pipeline insulation

INTRODUCTION

This product is a type of blend polyols premixed with HCFC-141B, which is specially researched for rigid PUF to produce thermal insulation pipes. It is widely used in steam pipes, liquefied nature gas running pipes, oil pipes and other fields. The characteristics are as follows:

(1) good flowability, by regulating formula to suit different pipe diameters.

(2) excellent low temperature dimensional stability

PHYSICAL PROPERTY

| Appearance |

Light yellow to brown transparent liquid |

| Hydroxyl value mgKOH/g |

300-450 |

| Dynamic viscosity(25℃) mPa.S |

200-500 |

| Density (20℃) g/ml |

1.10-1.16 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

TECHNOLOGY AND REACTIVITY (Component temperature is 20℃, the actual value is varied according to pipe diameter and processing condition.)

|

|

Manual mixing |

High pressure machine |

| Ratio(POL/ISO) |

1:1.10-1.1.60 |

1:1.10-1.60 |

| Rise time s |

20-40 |

15-35 |

| Gel time s |

80-200 |

80-160 |

| Tack free time s |

≥150 |

≥150 |

| Free density kg/m3 |

25-40 |

24-38 |

FOAM PERFORMANCES

| Mold density | GB 6343 | 55-70kg/m3 |

| Closed-cell rate | GB 10799 |

≥90% |

| Thermal conductivity (15℃) | GB 3399 |

≤24mW/(m.K) |

| Compression strength | GB/T8813 | ≥200kPa |

| Water absorption | GB 8810 |

≤3(V/V)% |

| Dimensional stability 24h -30℃ |

GB/T8811 |

≤1.0% |

|

24h 100℃ |

≤1.5% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

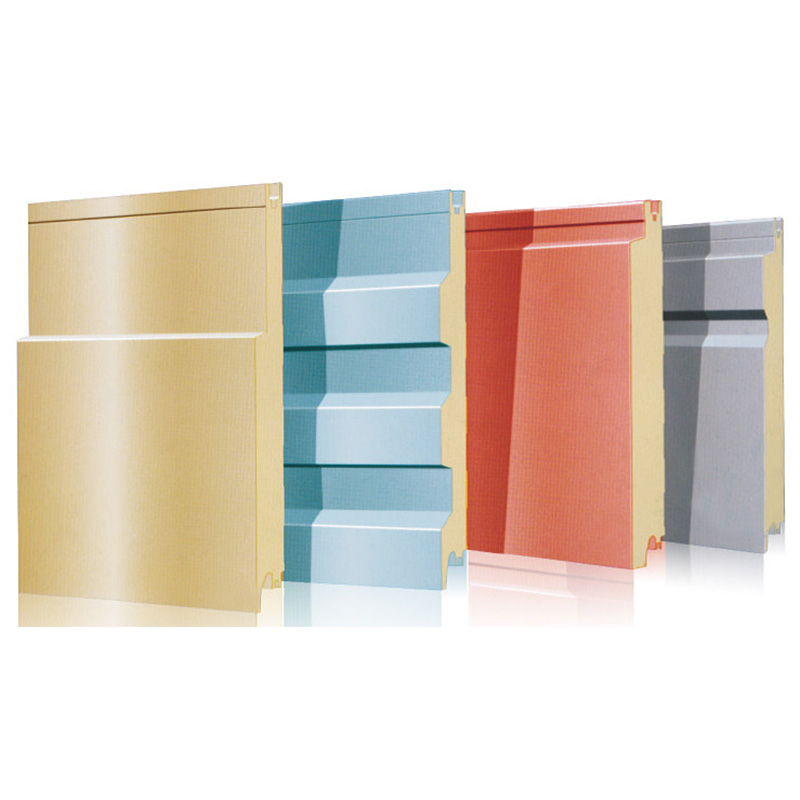

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Manufacturer for Pu Binder For Bonding Scrap Foam - Donpipe 302 HCFC-141b base blend polyols for pipeline insulation – INOV , The product will supply to all over the world, such as: Detroit, Montreal, Puerto Rico, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!