Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV Detail:

Donpanel 422 HCFC-141b base blend polyols for continuous PUR

INTRODUCTION

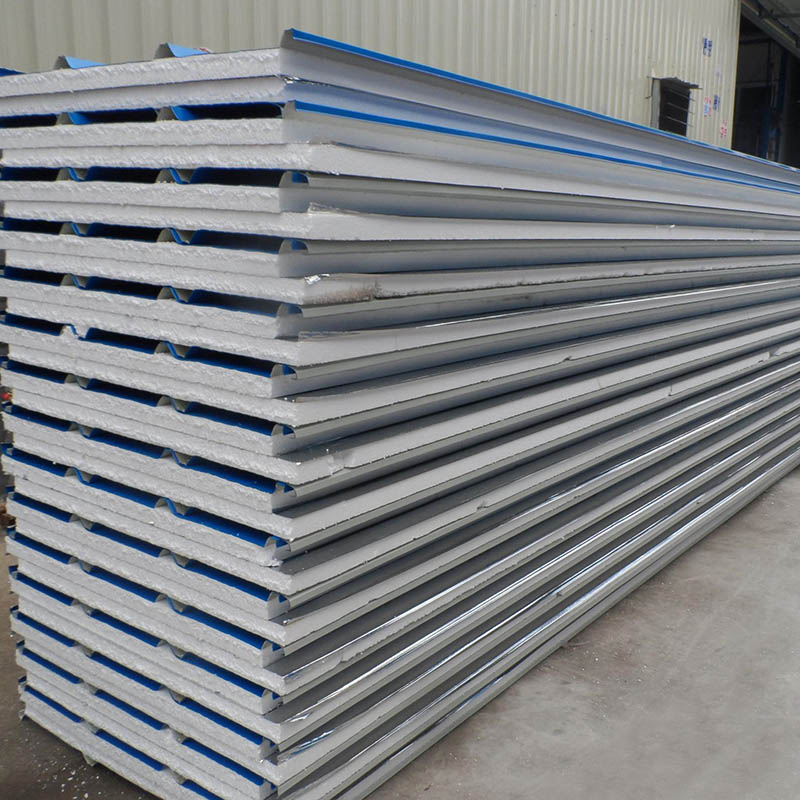

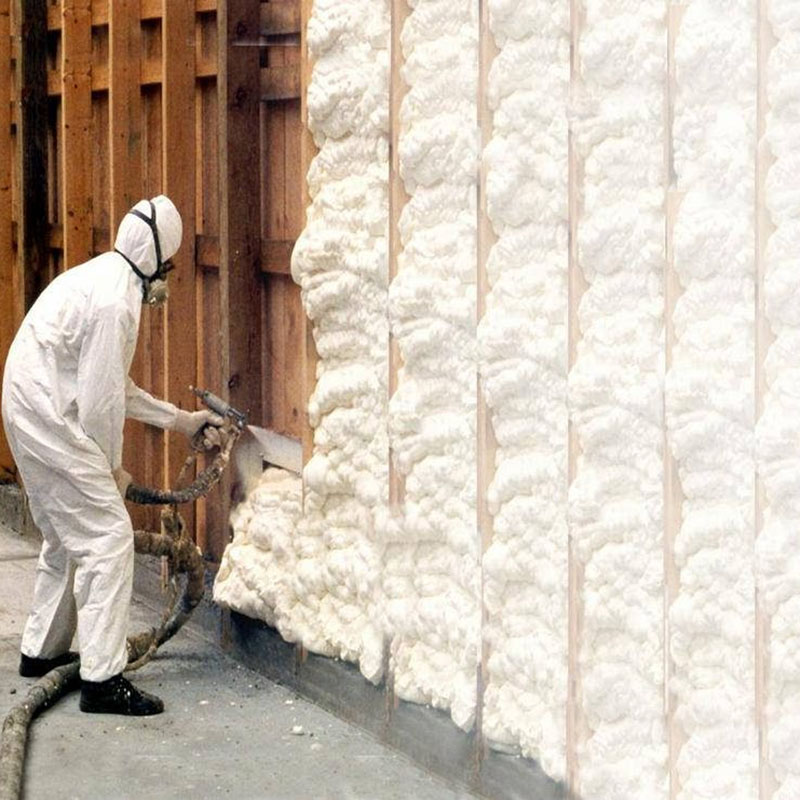

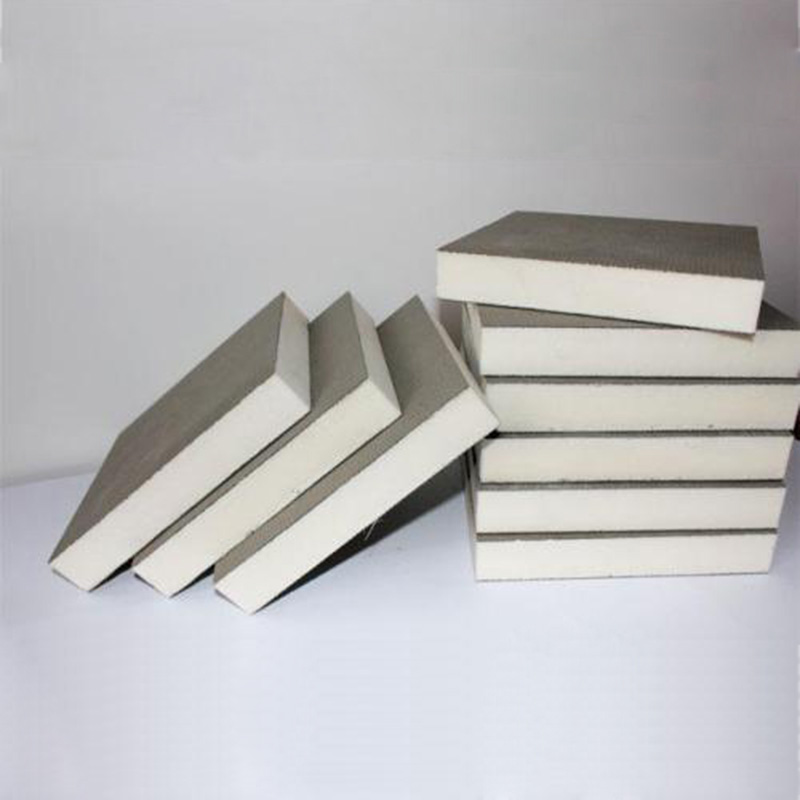

DonPanel 422/ PUR blend polyols is a compound which consists of polyether polyols, surfactants, catalysts, HCFC-141B and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardant and other advantages. It is widely used to produce continuous sandwich panels, corrugated panels etc, which applies to make cold stores, cabinets, portable shelters and so on.

PHYSICAL PROPERTY

|

Appearance |

Light yellow transparent viscous liquid |

|

Hydroxyl value mgKOH/g |

300-340 |

|

Dynamic viscosity (25℃) mPa.S |

300-400 |

|

Density (20℃) g/ml |

1.12-1.16 |

|

Storage temperature ℃ |

10-25 |

|

Storage stability month |

6 |

RECOMMENDED RATIO

|

Raw materials |

PBW |

|

DonPanel 422 blend polyols |

100 |

|

Isocyanate |

120-130 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High temperature machine |

|

Raw material temperature ℃ |

20-25 |

20-25 |

|

Mould temperature ℃ |

35-45 |

35-45 |

|

Cream time s |

8-16 |

6-10 |

|

Gel time s |

30-60 |

30-40 |

|

Free density kg/m3 |

28.0-35.0 |

33.0-35.0 |

FOAM PERFORMANCES

|

Mold density |

GB 6343 |

≥40kg/m3 |

|

Closed-cell rate |

GB 10799 |

≥90% |

|

Thermal conductivity(15℃) |

GB 3399 |

≤22mW/(m.K) |

|

Compression strength |

GB/T 8813 |

≥140kPa |

|

Adhesive strength |

GB/T 16777 |

≥120kPa |

|

Dimensional stability 24h -20℃ 24h 100℃ |

GB/T 8811 |

≤1% ≤1.5% |

|

Flame retardant grade |

GB/T8624 |

B2 |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Manufacturer for Pu Binder For Bonding Scrap Foam - Donpanel 422 HCFC-141b base blend polyols for continuous PUR – INOV , The product will supply to all over the world, such as: UAE, Macedonia, Canada, We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.