Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 822PIR HCFC-141B base blend polyols for continuous PIR block foam – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 822PIR HCFC-141B base blend polyols for continuous PIR block foam – INOV Detail:

Donfoam 822PIR HCFC-141B base blend polyols for continuous PIR block foam

INTRODUCTION

DonFoam 822/PIR is a kind of blend polyols with hcfc-141b foaming agent, with polyol as the main raw material, mixed with special auxiliary agent, suitable for the insulation of construction, transportation, shell and other products .This material is specially developed for continuous line .The polyurethane product prepared by reacting it with isocyanate has the following advantages:

1. Foam has uniform strength and dimensional stability in all directions

2. The foam products can be cut into different shapes according to the requirements of the product

3. Excellent thermal insulation performance

PHYSICAL PROPERTY

|

DonFoam 812/PIR |

|

| Appearance

OH value mgKOH/g Dynamic viscosity (25℃) mPa.S Density (20℃) g/ml Storage temperature ℃ Storage stability ※ /month |

Light yellow to brown transparent liquid 150-250 200-300 1.15-1.25 10-25 6 |

RECOMMENDED RATIO

|

Pbw |

|

| DonFoam 812/PIR

Isocyanate |

100 150-200 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Manual Mix |

High pressure |

|

| Raw Material Temperature ℃

Cream time S Gel time S Free density Kg/m3 |

20-25 20-50 160-300 40-50 |

20-25 15-45 140-260 40-50 |

FOAM PERFORMANCES

| Overall Molding Density

Closed-cell Rate Initial Thermal Conductivity(15℃) Compressive Strength Dimensional Stability 24h -20℃ 24h 100℃ Flammability |

GB/T 6343 GB/T 10799 GB/T 3399 GB/T 8813 GB/T 8811

GB/T 8624 |

≥40 Kg/m3

≥90% ≤22mW/m.k ≥150 KPa ≤0.5% ≤1.0% B2、B1 |

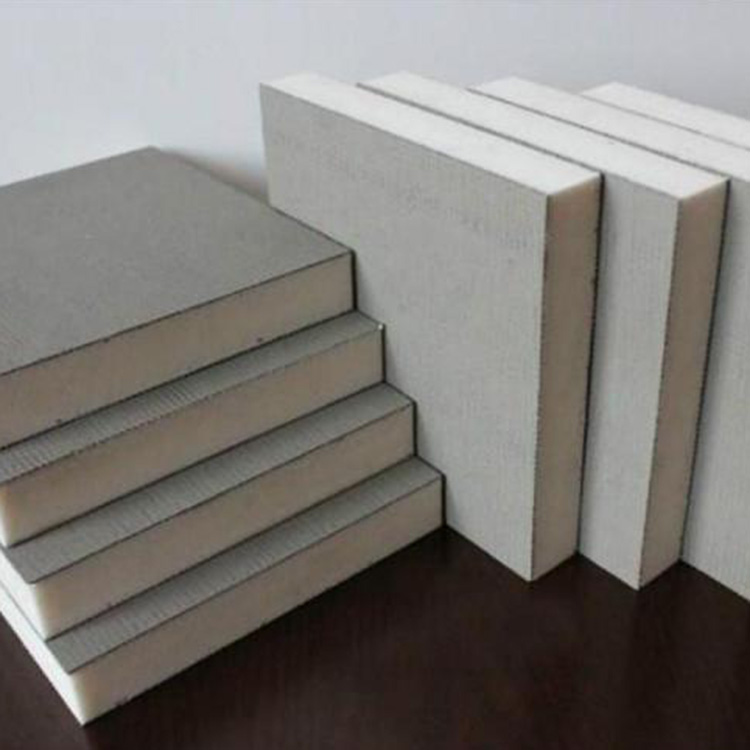

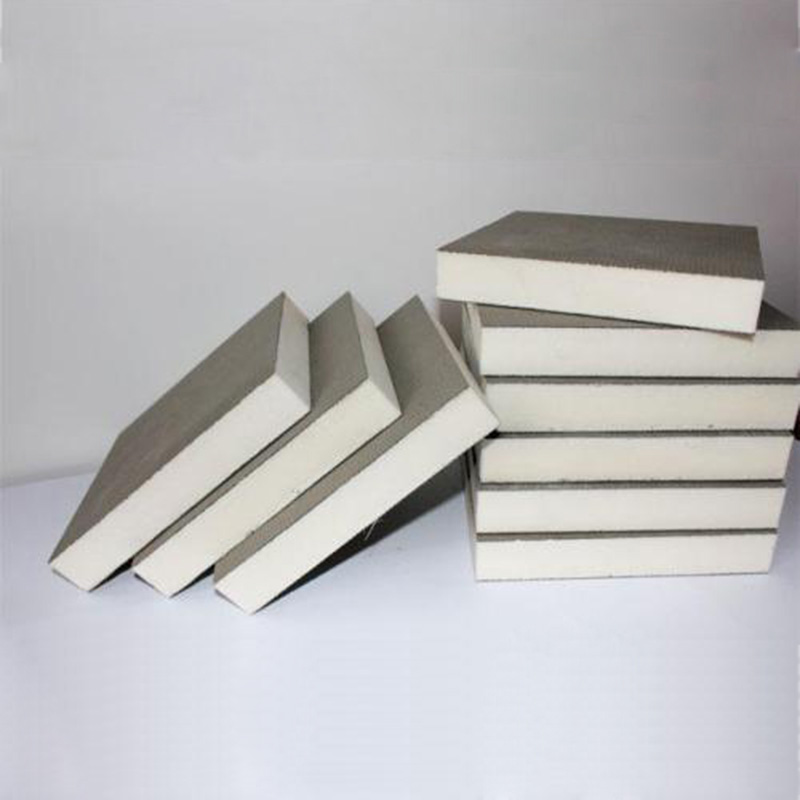

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Manufacturer for Pu Binder For Bonding Scrap Foam - Donfoam 822PIR HCFC-141B base blend polyols for continuous PIR block foam – INOV , The product will supply to all over the world, such as: Egypt, St. Petersburg, Argentina, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!