Manufacturer for Pu Binder For Bonding Scrap Foam - Doncool 106 CP/ HFO-1233zd base blend polyols – INOV

Manufacturer for Pu Binder For Bonding Scrap Foam - Doncool 106 CP/ HFO-1233zd base blend polyols – INOV Detail:

Doncool 106 CP/ HFO-1233zd base blend polyols

INTRODUCTION

DonCool 106 blend polyols use CP mixed with HFO-1233zd as blowing agent, it applies to refrigerators, freezers, electric water heaters and other products thermal insulation, the characteristics are as follows,

1-Excellent flowability, foam density distributes uniformity, low thermal conductivity

2- Outstanding low temperature dimension stability and cohesiveness

3-Demoulding time is 4-8min.

PHYSICAL PROPERTY

| Appearance |

Yellowish-brown transparent liquid |

| Hydroxyl Value mgKOH/g |

320-370 |

| Dynamic Viscosity /25℃ mPa.s |

4000-5000 |

| Specific Gravity /20℃ g/ml |

1.05-1.10 |

| Storage Temperature ℃ |

10-20 |

| Shelf life (unmixed materials)※ Month |

3 |

| Shelf life (premixed materials) ※ Month |

1 (Material Temperature below 20℃) |

※Store in dry original drums/IBCs at recommended storage temperature.

RECOMMENDED RATIO

|

pbw |

|

| DonCool 106 blend polyols |

100 |

| CP |

12.5 |

| LBA |

7 |

| ISO |

143.4-149.4 |

TECHNOLOGY AND REACTIVITY CHARACTERISTICS (Material Temperature is 20℃, the actual value varied as per process conditions)

|

Manual Mixing(low pressure machine) |

High Pressure Machine Mixing |

|

| Cream Time s

Gel time s Tack free time s Free density kg/m3 |

8-10 70-80 100-130 23-23.5 |

6-8 50-70 70-100 22-23 |

FOAM PERFORMANCES

| Moulding Density | GB/T 6343 | 30-32kg/m3 |

| Closed-cell rate | GB/T 10799 | ≥90% |

| Thermal Conductivity(10℃) | GB/T 3399 | ≤18.5 mW/(m.K) |

| Compressive strength | GB/T 8813 | ≥140kPa |

| Dimensional stability 24h -20℃ | GB/T 8811

|

≤1.0% |

|

24h 100℃ |

≤1.5% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

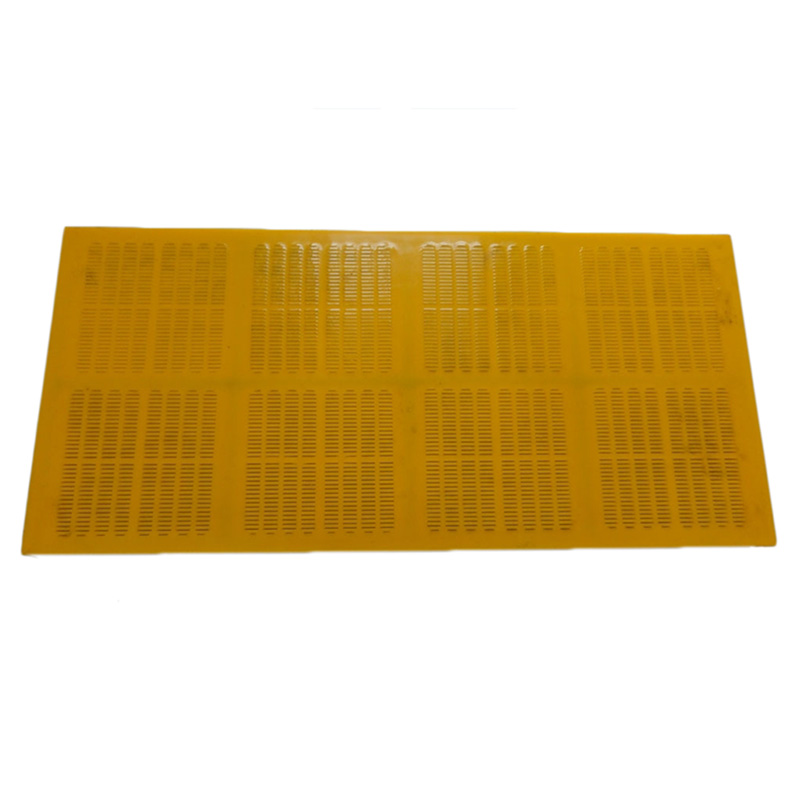

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Manufacturer for Pu Binder For Bonding Scrap Foam - Doncool 106 CP/ HFO-1233zd base blend polyols – INOV , The product will supply to all over the world, such as: Algeria, Malta, Vietnam, Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don't hesitate to contact us. We will do our best to meet your needs.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!