Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV

Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV Detail:

High hardness two component system

DESCRIPTION

It’s used to make rods, caster wheels, rollers, Sealing rings, sieve plates. It is specially used for some high performance Pu products.

Characteristic: Excellent abrasion resistance, Nice mechanical properties, High temperature resistance, Acid resistance, color can be regulated by adding pigment.

SPECIFICATION

|

Type |

D4136 |

D4336 |

D4155 |

D4160 |

D4190 |

D4590 |

|

NCO content /% |

3.3±0.1 |

3.6±0.2 |

5.5±0.2 |

6.0±0.2 |

9.0±0.2 |

9.0±0.2 |

|

Appearance at 20 ℃ |

White solid |

|||||

|

Curing agent 100g PU Prepolymer/g |

MOCA 9.7 |

MOCA 10.5 |

MOCA 16 |

MOCA 17.5 |

MOCA 25.5 |

BDO 9 |

|

Mixing temperature /℃(PU Prepolymer) |

90/120 |

90/120 |

75/110 |

80/120 |

70/110 |

80/40 |

|

Gel time /min |

8 |

8 |

5 |

4.5 |

2 |

5 |

|

Hardness (Shore A) |

60±1 |

82±1 |

91±1 |

94±1 |

75D |

93±2 |

AUTOMATIC CONTROL

The production is controlled by DCS system, and packing by automatic filling machine. Package is 200KG/DRUM Or 20KG/DRUM.

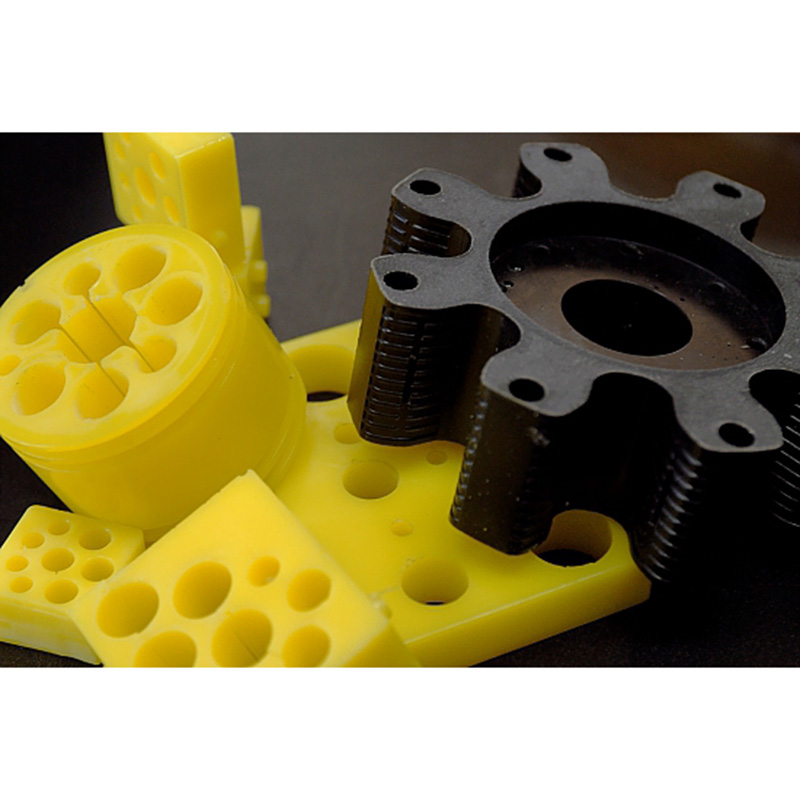

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Manufacturer for Pouring Pu Material - PCL Prepolymer – INOV , The product will supply to all over the world, such as: Mexico, Liberia, Russia, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.