High definition Donspray 502 Hcfc-141b Base Blend Polyols - Donspray 504 HFC-245fa base blend polyols – INOV

High definition Donspray 502 Hcfc-141b Base Blend Polyols - Donspray 504 HFC-245fa base blend polyols – INOV Detail:

Donspray 504 HFC-245fa base blend polyols

INTRODUCTION

DonSpray504 is spray blend polyols, blowing agent is 245fa instead of HCFC-141B, it reacts with isocyanate to produce foam which has excellent performances, which are as follows,

1) fine and uniformity cells

2) low thermal conductivity

3) perfect flame resistance

4) good low-temperature dimensional stability.

It applies to all kinds of thermal insulation engineering which uses the spray technology, such as cold rooms, pots, large-scale pipelines and construction metope etc.

PHYSICAL PROPERTY

| Appearance |

Pale yellow to brown viscous liquid |

| Hydroxyl Value mgKOH/g |

200-300 |

| Dynamic viscosity(25℃) mPa.S |

100-200 |

| Specific gravity (20 ℃ ) g/ml |

1.12-1.20 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

RECOMMENDED RATIO

| Raw materials |

pbw |

| DonSpray 504 blend polyols |

100 g |

| Isocyanate MDI |

100-105g |

Reactivity Characteristics (The temperature of the system is 20℃,and the exact value varied depending on processing condition)

| Cream Time s |

3-5 |

|

Gel Time s |

6-10 |

FOAM PERFORMANCES

| Items |

Metric Unit |

Imperial Unit |

||

| Spray Density | GB 6343 | ≥35kg/m3 | ASTM D 1622 | ≥2.18 lb/ft3 |

| Closed-cell Rate | GB 10799 | ≥90% | ASTM D 1940 | ≥90% |

| Initial Thermal Conductivity(15℃) | GB 3399 | ≤24mW/(m.K) | ASTM C 518 | ≥2.16/inch |

| Compressive Strength | GB/T8813 | ≥150kPa | ASTM D 1621 | ≥21.76PSI |

| Adhesive Strength | GB/T16777 | ≥120kPa | ASTM D 1623 | ≥17.40PSI |

| Dimentional Stability 24h -20℃ | GB/T8811 | ≤1% | ASTM D 2126 | ≤1% |

| 24h 70℃ | ≤1.5% | ≤1.5% | ||

| Water Absorption | GB 8810 | ≤3% | ASTM E 96 | ≤3% |

| Fire Resistance | GB 8624 | Class B2 | ASTM D2863-13 | Class B2 |

PACKAGE

220kg/drum or 1000kg/IBC, 20,000kg/flexi tank or ISO Tank.

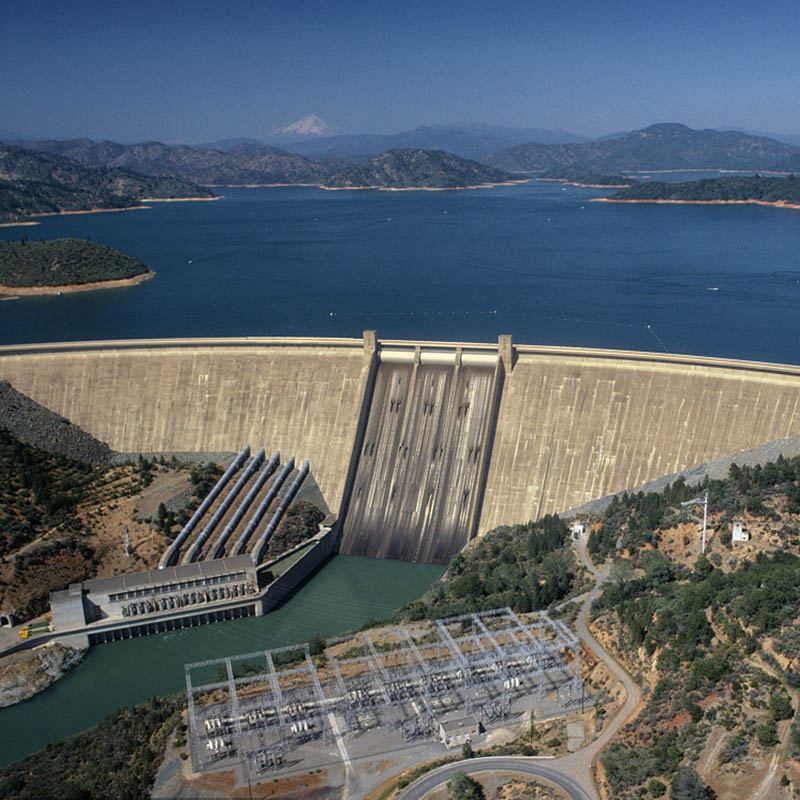

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for High definition Donspray 502 Hcfc-141b Base Blend Polyols - Donspray 504 HFC-245fa base blend polyols – INOV , The product will supply to all over the world, such as: Greek, South Korea, Iraq, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!