Factory wholesale Slow Resilience - Integral Skin Foam System – INOV

Factory wholesale Slow Resilience - Integral Skin Foam System – INOV Detail:

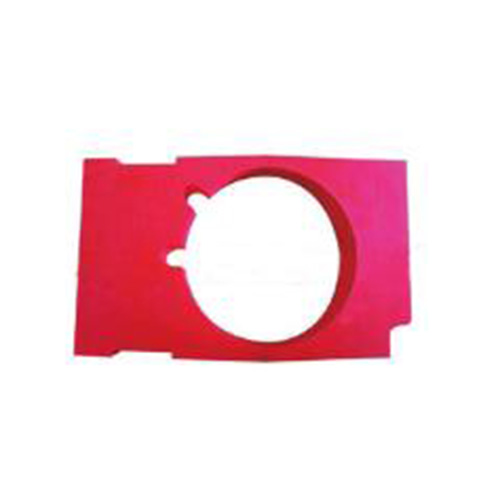

Integral Skin Foam System

APPLICATIONS

This kind of product is widely used for making armrest,steering wheel,seat cushion,etc.

CHARACTERISTICS

DZJ-A is type of blend Polyol combined with base polyol, cross-linking agent, blowing agent, cat. and some other agent. DZJ-B is isocynate combined with MDI.&modified MDI. The system is suitable to produce integral skin foam which without TDI, eco-friendly, low smell, suitable hardness.

SPECIFICATION

|

Item |

DZJ-01A/01B |

DZJ-02A/02B |

|

Ratio(Polyol/Iso) |

100/40-100/45 |

100/50-100/55 |

|

Mould Temperature ℃ |

50-55 |

40-50 |

|

Demolding Time min |

6-7 |

3-4 |

|

FRD kg/m3 |

120-150 |

120-150 |

|

Overall Density kg/m3 |

350-400 |

350-400 |

|

Hardness Shore A |

65-75 |

70-80 |

AUTOMATIC CONTROL

The production is controlled by DCS systems, and packing by automatic filling machine.

RAW MATERIAL SUPPLIERS

Basf, Covestro, Wanhua…

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for Factory wholesale Slow Resilience - Integral Skin Foam System – INOV , The product will supply to all over the world, such as: Panama, Singapore, Latvia, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.