Factory wholesale Donfoam 603 Ecomate Base Blend Polyols - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV

Factory wholesale Donfoam 603 Ecomate Base Blend Polyols - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV Detail:

Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam

INTRODUCTION

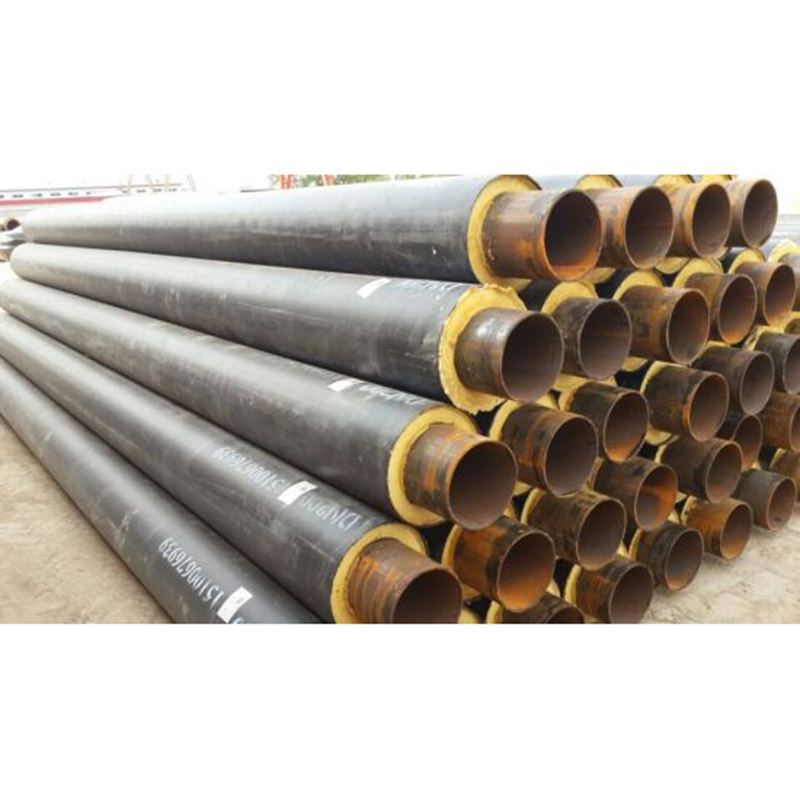

Donfoam825 blend polyether polyol used in the manufacture of high flame retardant PIR block foam with HFC-365mfc/227 as foaming agent, products and isocyanate reaction by the formation of the foam has uniform foam cell , low thermal conductivity, thermal insulation performance is good, flame retardant performance is good, low temperature no shrinking crack etc. Widely used in the process of all kinds of insulation work such as: building external wall, cold storage, tanks, large pipes etc.

PHYSICAL PROPERTY

| Appearance |

Light yellow to brown transparent liquid |

| Dynamic viscosity(25℃) mPa.S |

300±100 |

| Density (20℃) g/ml |

1.20±0.1 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

RECOMMENDED RATIO

| Raw materials |

pbw |

| DK-1101 Blend Polyether Polyol |

100 |

| Isocyanate |

180±20 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Items |

Manual mixing |

High pressure machine |

| Raw material temperature ℃ |

20-25 |

20-25 |

| Mould temperature ℃ |

50-60 |

50-60 |

| Cream time s |

25-35 |

20-30 |

| Gel time s |

90.-130 |

70-100 |

| Tack free time s |

150-200 |

120-160 |

| Free density kg/m3 |

28-30 |

27-29 |

MACHINERY FOAM PERFORMANCES

| Overall Mold density | GB 6343 |

≥45kg/m3 |

| Molding Core Density |

≥40kg/m3 |

|

| Closed-cell Rate | GB 10799 | ≥90% |

| Initial Thermal Conductivity(15℃) | GB 3399 |

≤24mW/(m.K) |

| Compressive Strength | GB/T8813 |

≥150kPa |

| Dimentional Stability 24h -20℃

24h 70℃ |

GB/T8811 |

≤1% ≤1.5% |

| Water Absorption Rate | GB 8810 |

≤3% |

| Flammability | GB 8624 |

B1/B2/B3 |

| Closed-cell Rate | GB 10799 |

≥90% |

| Initial Thermal Conductivity(15℃) | GB 3399 |

≤24mW/(m.K) |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for Factory wholesale Donfoam 603 Ecomate Base Blend Polyols - Donfoam 825PIR HFC-365mfc base blend polyols for continuous PIR block foam – INOV , The product will supply to all over the world, such as: Malaysia, Congo, United States, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.