Factory Supply Polyurethane Foam Insole System - DSPU-601 – INOV

Factory Supply Polyurethane Foam Insole System - DSPU-601 – INOV Detail:

DSPU-601

INTRODUCTION

DSPU-601 is two-component polyurea spray type combination, which is used in a variety of base material protection. 100% solid content, no solvents, no volatile, little or no odor, strictly comply with the VOC limit standard, belongs to the environmentally friendly materials.

PHYSICAL PROPERTIES

| Item | Unit | Polyether component | Isocyanate component |

| Appearance | viscous liquid | viscous liquid | |

| Density(20℃) | g/cm3 | 1.02±0.03 | 1.08±0.03 |

| Dynamic Viscosity(25℃) | mPa·s | 650±100 | 800±200 |

| shelf life | month | 6 | 6 |

| Storage Temperature | ℃ | 20-30 | 20-30 |

PRODUCT PACKAGING

200kg /drum

STORAGE

B component (isocyanate) is moisture sensitive. Unused raw materials should be stored in a sealed drum, avoid moisture intrusion .A component (polyether) should stir well before use.

PACKAGING

DTPU-401 is sealed in 20kg or 22.5kg pails and transported in wooden cases.

POTENTIAL HAZARDS

Part B (isocyanates) stimulate the eye, respiratory and skin through breathing and skin contact, and possibly sensitization.

When contact part B ( isocyanates), necessary preventive measures should be taken according to material safety date sheet (MSDS).

WASTE DISPOSAL

With reference to the material safety date sheet (MSDS) of the product, or deal with it in accordance with local laws and regulations.

PROPOSAL OF PROCESS

| Unit | Value | Test Methods | |

| Mix ratio | By volume | 1:1(A:B) | |

| GT | s | 5-10 | GB/T 23446 |

| Surface dry time | s | 15-25 | |

| Temperature of material

-part A -part B |

℃ | 65-70 | |

| Pressure of material

-Part A -Part B |

PSI | 2500 |

PHYSICAL PROPERTIES OF FINISHED PRODUCT

| DSPU-601 | Unit | Test Methods | |

| Hardness | ≥80 | Shore A | GB/T 531.1 |

| Tensile Strength | ≥16 | MPa | GB/T 16777 |

| Elongation at break | ≥450 | % | |

| Tear strength | ≥50 | N/mm | GB/T 529 |

| impervious | ℃ | GB/T 16777 | |

| Bibulous rate | ≤5 | % | GB/T 23446 |

| solid content | 100 | % | GB/T 16777 |

| Adhesive strength, dry base material | ≥2 | Mpa |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

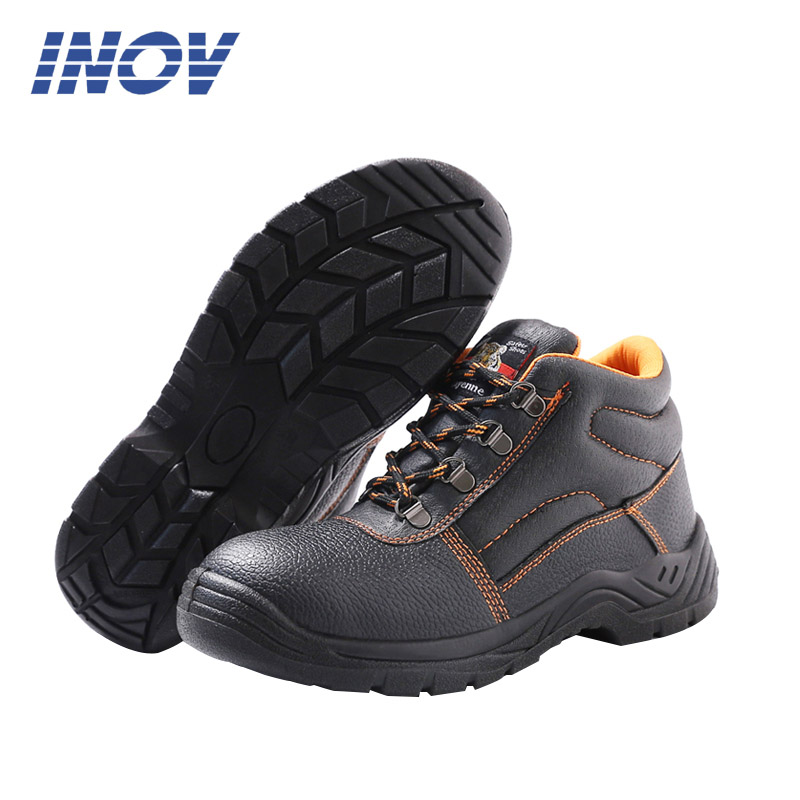

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Factory Supply Polyurethane Foam Insole System - DSPU-601 – INOV , The product will supply to all over the world, such as: Curacao, Danish, Bogota, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.