Best quality Pu Binder For Mould Processing Product - Donpanel 423PIR CP/IP base blend polyols for continuous PUR – INOV

Best quality Pu Binder For Mould Processing Product - Donpanel 423PIR CP/IP base blend polyols for continuous PUR – INOV Detail:

Donpanel 423PIR CP/IP base blend polyols for continuous PUR

INTRODUCTION

DonPanel 423/PIR is a kind of blend polyether polyol which adopts cyclopentane as foaming agent, takes polyol as the main raw material and is mixed with special auxiliary agent. It is suitable for thermal insulation of building boards, cold storage boards and other products.This material is specially developed for continuous line .The polyurethane product prepared by reacting it with isocyanate has the following advantages:

– No greenhouse effect and does not damage the ozone layer

- Good fluidity and uniform foam density

–Excellent dimensional stability and fire resistance

PHYSICAL PROPERTY

|

DonPanel 423/PIR |

|

| Appearance

Hydroxyl value mgKOH/g Dynamic viscosity (25℃) mPa.S Density (20℃) g/ml Storage temperature ℃ Storage stability months |

Light yellow transparent viscous liquid 150-250 300-500 1.15-1.25 10-25 6 |

RECOMMENDED RATIO

|

Pbw |

|

| DonPanel 423/PIR

Isocyanate |

100 150-200 |

TECHNOLOGY AND REACTIVITY (the exact value varies depending on processing conditions)

|

Manual mix |

High pressure |

|

| Raw material temperature ℃

CT S GT S TFT S Free density Kg/m3 |

20-25 7-20 25-55 30-60 35-40 |

20-25 5-15 20-40 30-55 34-40 |

FOAM PERFORMANCES

| Mold density

Close-cell rate Thermal conductivity (10℃) Compression strength) Dimensional stability 24h -20℃ 24h 100℃ Flammability |

GB/T 6343 GB/T 10799 GB/T 3399 GB/T 8813 GB/T 8811

GB/T 8624 |

≥42 Kg/m3

≥90% ≤22mW/m.k ≥120 KPa ≤0.5% ≤1.0% B3、B2 |

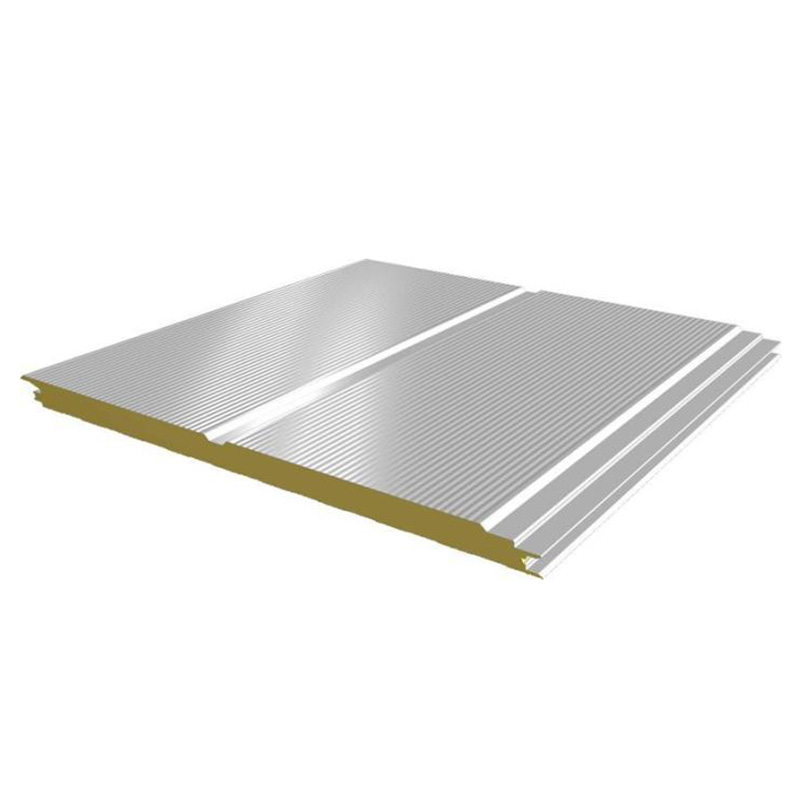

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for Best quality Pu Binder For Mould Processing Product - Donpanel 423PIR CP/IP base blend polyols for continuous PUR – INOV , The product will supply to all over the world, such as: Argentina, Johannesburg, Luxembourg, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.