2019 China New Design High Hardness Two Component System - Donpipe 301 water base blend polyols for pipeline insulation – INOV

2019 China New Design High Hardness Two Component System - Donpipe 301 water base blend polyols for pipeline insulation – INOV Detail:

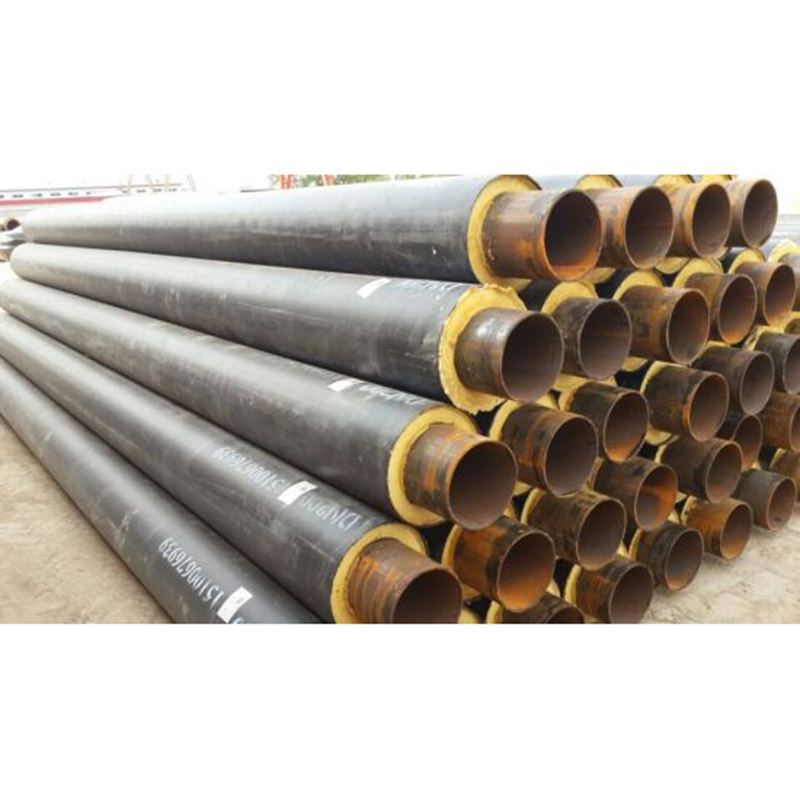

Donpipe 301 water base blend polyols for pipeline insulation

INTRODUCTION

This product is a type of blend polyols with water as foaming agent, which is specially researched for rigid PUF to produce thermal insulation pipes. It is widely used in steam pipes, liquefied nature gas running pipes, oil pipes and other fields. The characteristics are as follows:

(1) good flowability, by regulating formula to suit different pipe diameters.

(2) high temperature-resistance performance, long standing in 150℃

(3) excellent low temperature dimensional stability

PHYSICAL PROPERTY

| Appearance |

Light yellow to brown transparent liquid |

| Hydroxyl value mgKOH/g |

250-450 |

| Dynamic viscosity(25℃) mPa.S |

300-600 |

| Density (20℃) g/ml |

1.10-1.16 |

| Storage temperature ℃ |

10-25 |

| Storage stability month |

6 |

TECHNOLOGY AND REACTIVITY (Component temperature is 20℃, the actual value is varied according to pipe diameter and processing condition.)

|

|

Manual mixing |

High pressure machine |

| Ratio(POL/ISO) |

1:1.40-1.1.60 |

1:1.40-1.60 |

| Rise time s |

20-40 |

15-35 |

| Gel time s |

80-200 |

80-160 |

| Tack free time s |

≥150 |

≥150 |

| Free density kg/m3 |

34.0-36.0 |

33.0-35.0 |

FOAM PERFORMANCES

| Mold density | GB 6343 | 60-80kg/m3 |

| Closed-cell rate | GB 10799 |

≥90% |

| Thermal conductivity (15℃) | GB 3399 |

≤33mW/(m.K) |

| Compression strength | GB/T8813 | ≥250kPa |

| Water absorption | GB 8810 |

≤3(V/V)% |

| Dimensional stability 24h -30℃ | GB/T8811 |

≤1.0% |

|

24h 100℃ |

≤1.5% |

The data provided above are typical value, which are tested by our company. For our company’s products, the data included in the law do not have any constraints.

Product detail pictures:

Related Product Guide:

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for 2019 China New Design High Hardness Two Component System - Donpipe 301 water base blend polyols for pipeline insulation – INOV , The product will supply to all over the world, such as: Denver, Porto, Burundi, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!